Metal Fabrication

Services

Our comprehensive ability to manufacture custom parts has been carefully crafted to meet your needs. Our expertise covers cutting-edge technologies such as sheet metal fabrication and CNC machining, etc.

Explore our comprehensive selection of services that cater to a variety of needs, ensuring complete customer satisfaction.

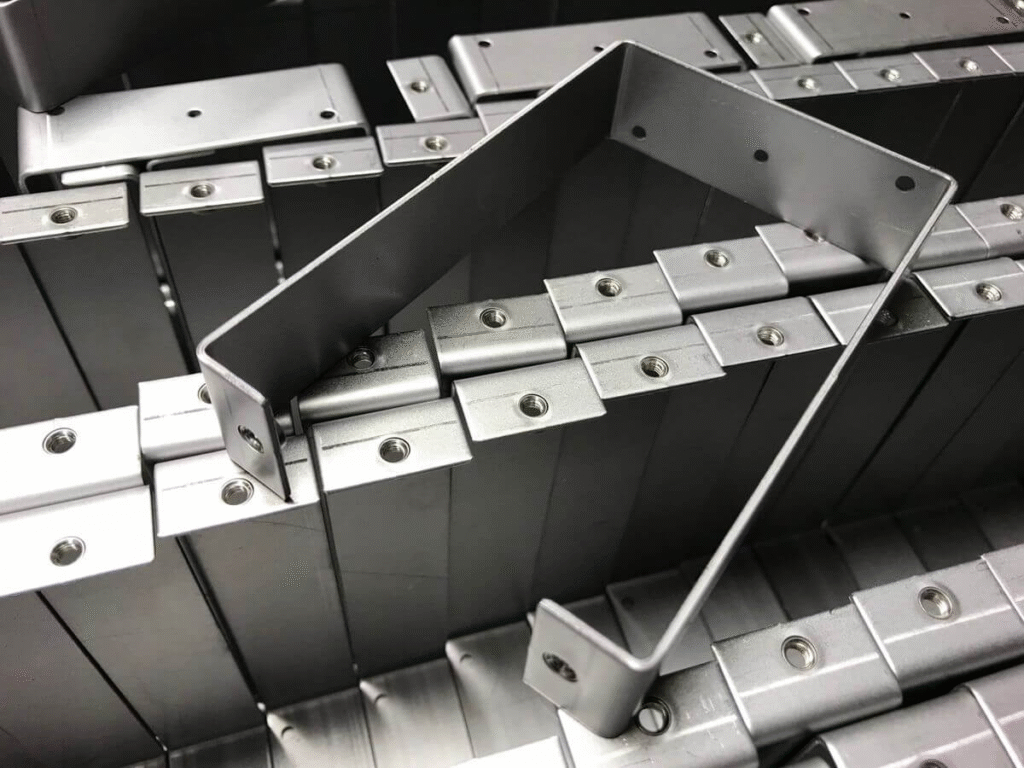

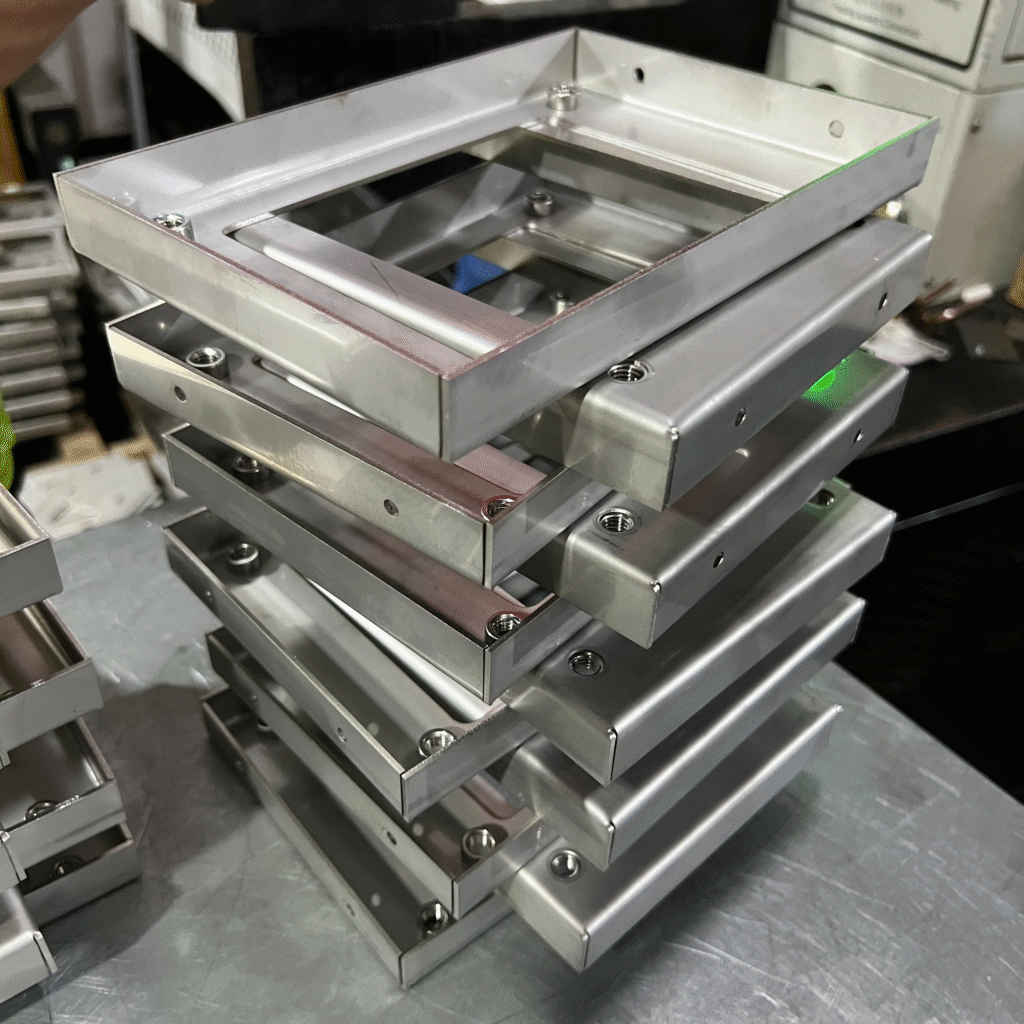

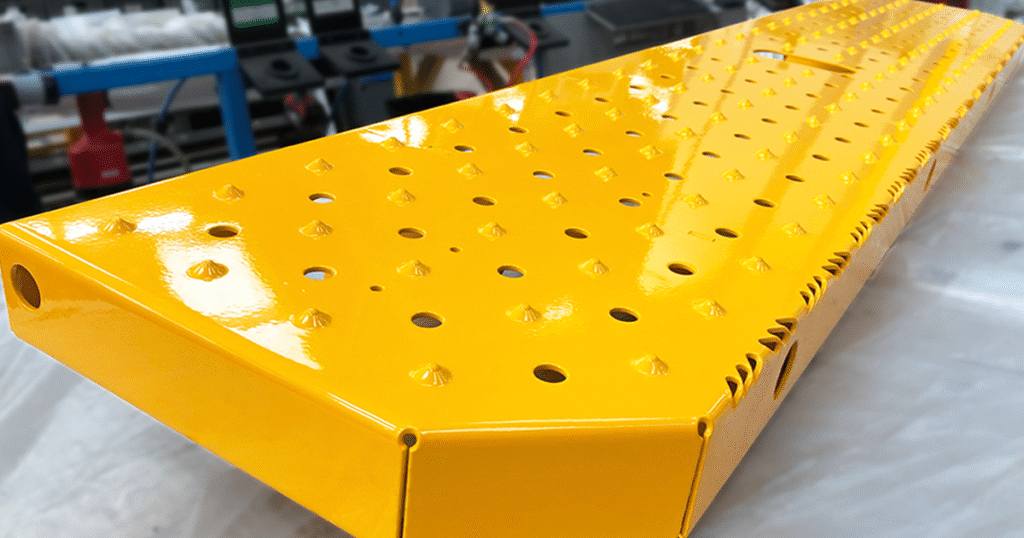

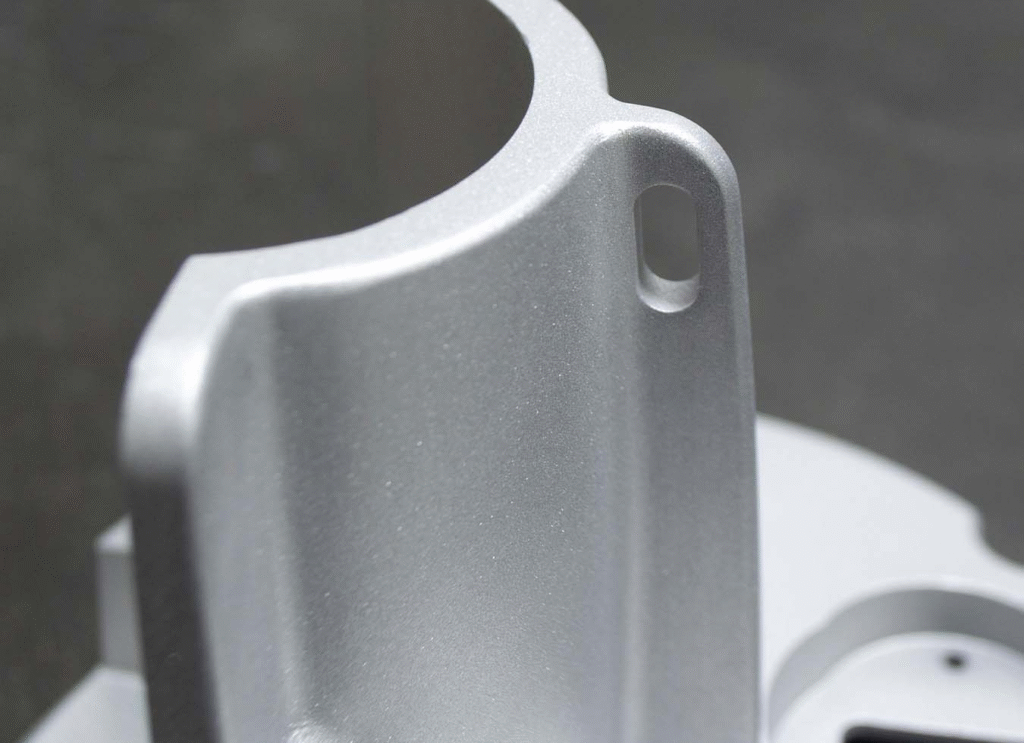

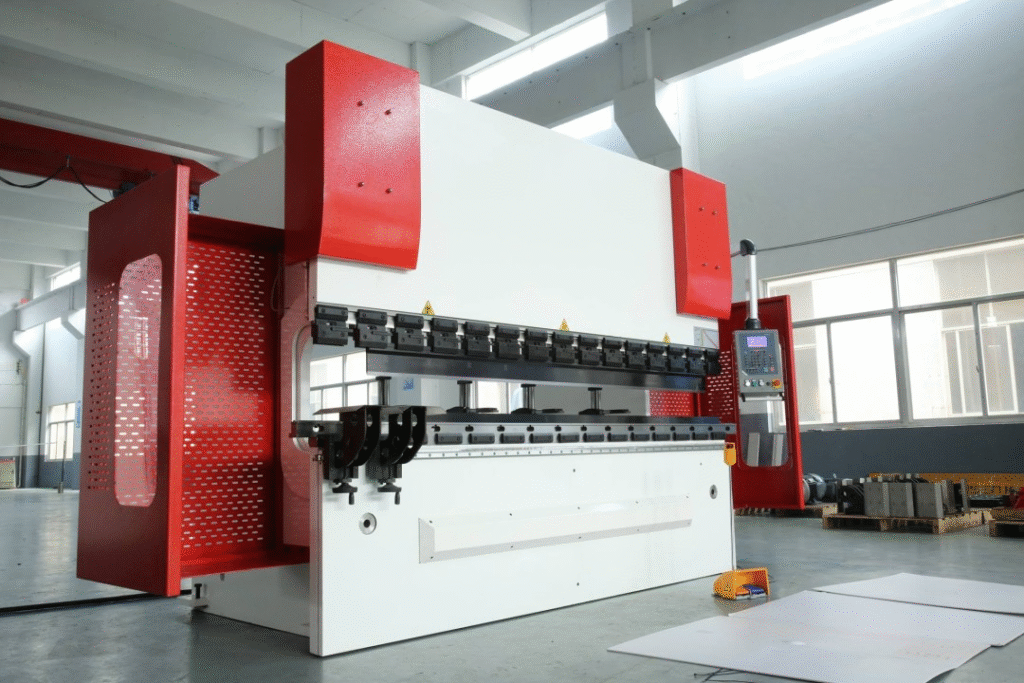

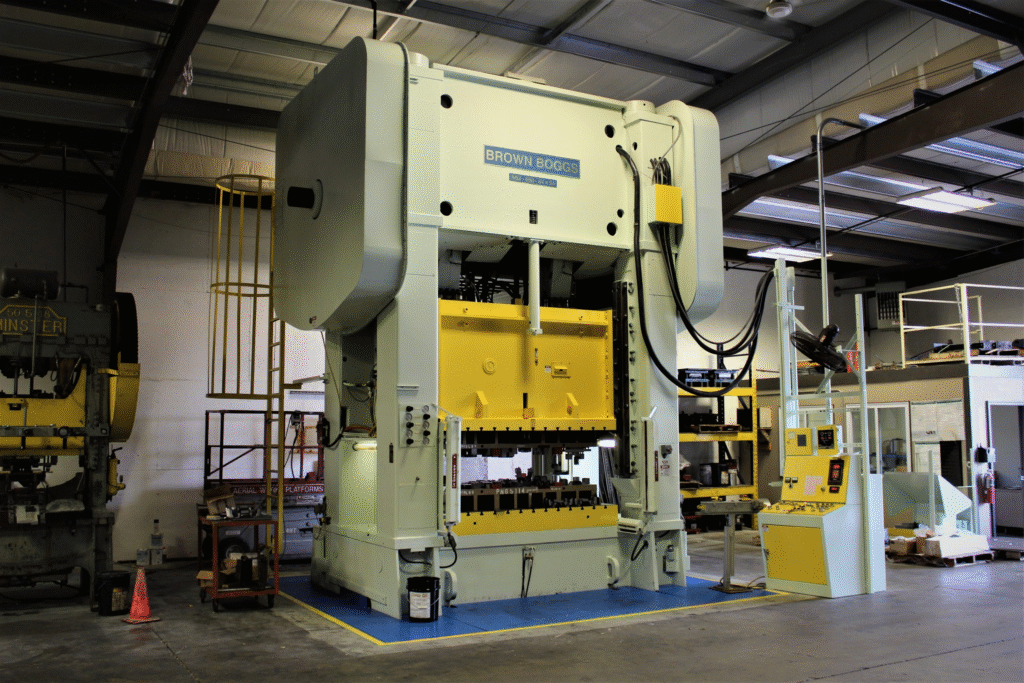

Sheet metal fabrication

Sheet metal fabrication is a valuable production method for creating functional components such as panels, brackets and enclosures.

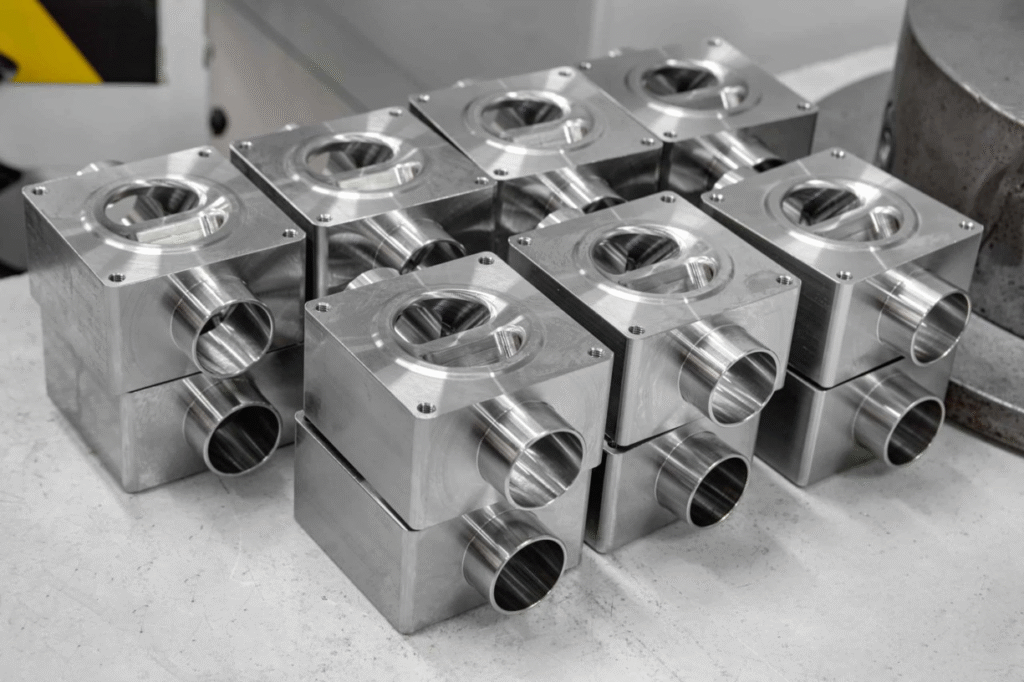

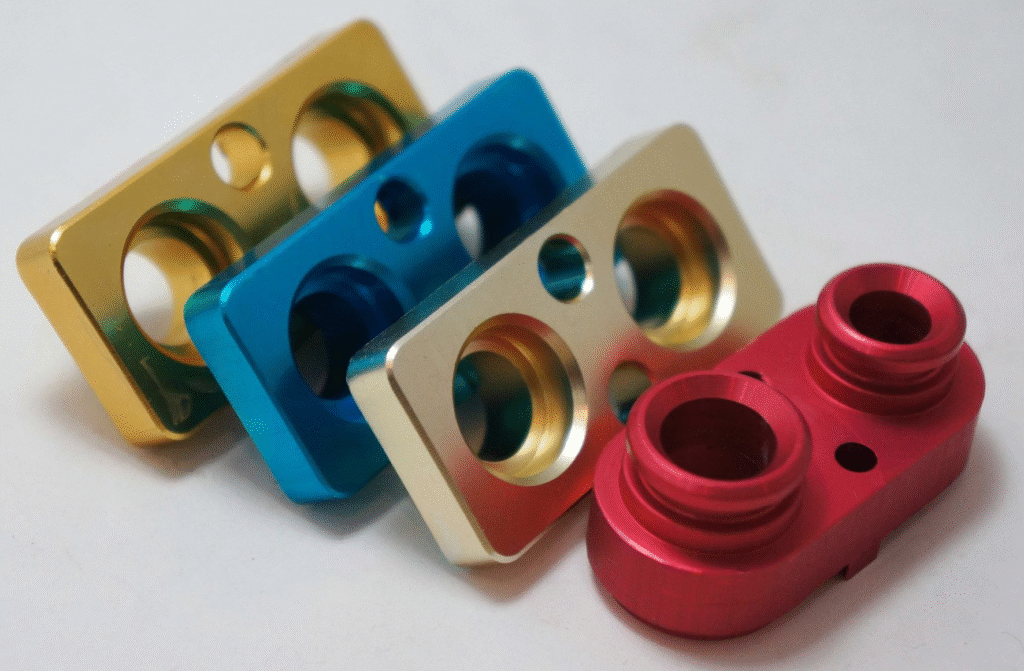

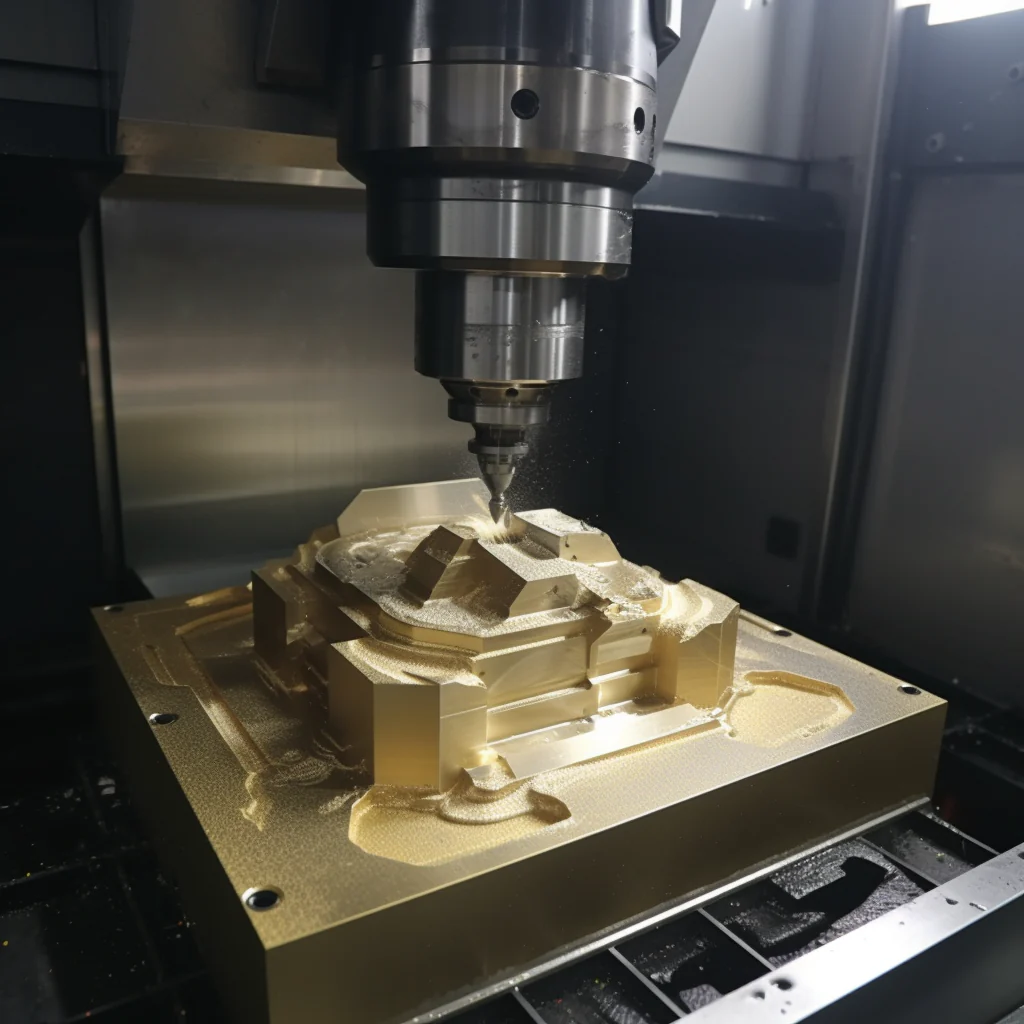

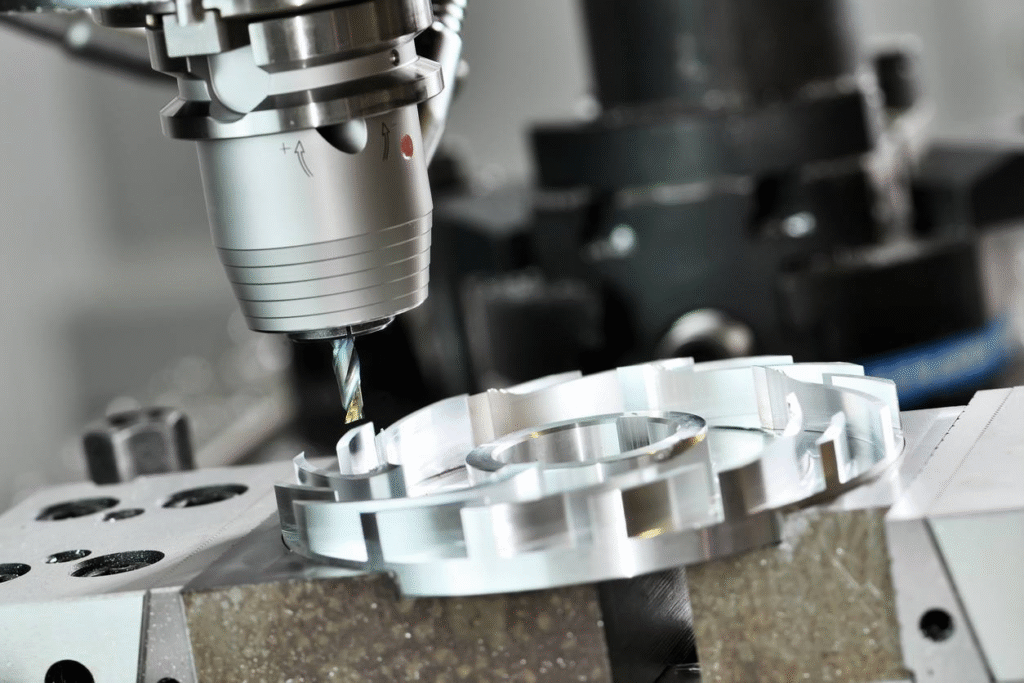

CNC Machining Capability

Provides close-tolerance CNC machining services, including 3, 4, 5-axis CNC milling, CNC turning and surface treatment services.

Finishing Services

Nice surface finishing services can both improve the aesthetics and function of a part.

Quality Inspection

Quality Management System has been approved and certified to the ISO 9001:2015 standard.

Fully Surface Finishing Service

All surface treatments available for metal parts

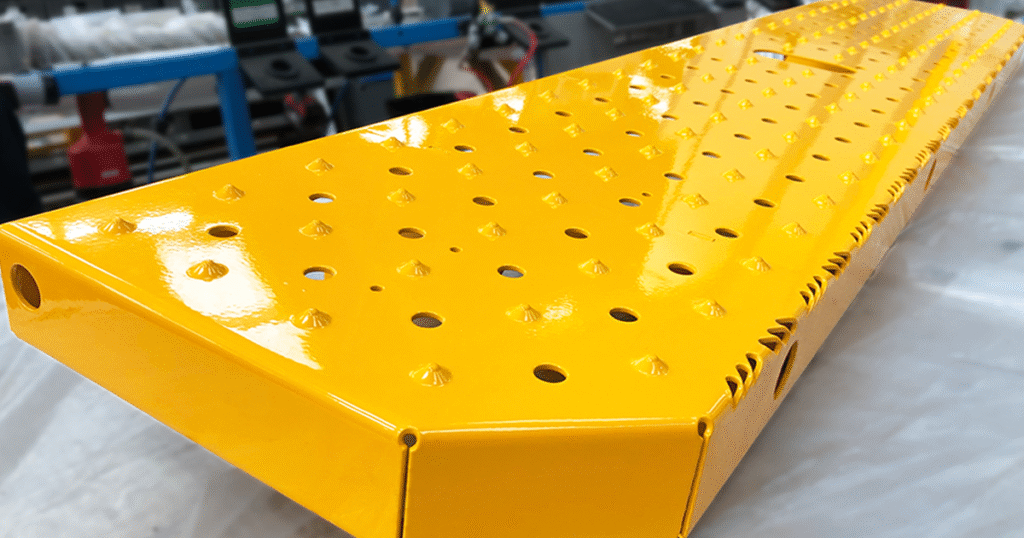

Powder Coating

Powder coating uses the phenomenon of corona discharge to add a thin layer of protective polymer to the surface, ranging in thickness from about 50 μm to 150 μm.

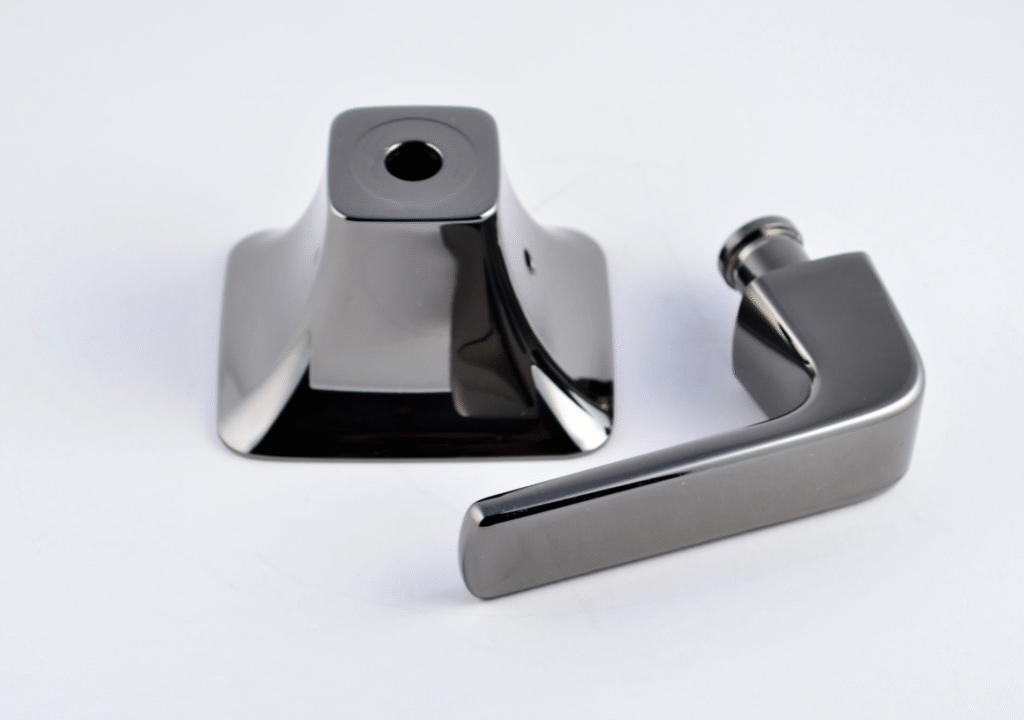

Electroplating

Electroplating is a finishing process that deposits metal onto a conductive surface using many specific materials such as chromium, gold, nickel and zinc nickel.

Anodizing

Anodizing has the characteristics of corrosion resistance, wear resistance and insulation, and can maintain the performance of parts for a long time.

Silk-screen Print

Laser etching is a process that alters the surface of a material to create a permanent mark. Commonly used include aluminum, stainless steel, and zinc.

Sandblasting

Sand blasting is the impact of fine abrasive glass bead particles on the part surface under high pressure, resulting in matte surface. Glass bead sizes from #80 to #220.

Chromate

Passivation is a method to transform the metal surface into a state that is not easily oxidized, and to delay the corrosion rate of the metal, Commonly used stainless steel.

Working Gallery

The Gallery aims to share the metal manufacturing knowledge, experience and skills we have accumulated over the years.

From Design to Production

VINLUK, specializing in metal fabrication since 2010

and offer a variety of services including sheet metal fabrication and CNC machining

Rapid Metal

Prototyping

Low – Volume

Manufacturing

On-Demand

Production

Quality Reports

Inspection is required for each process during the production process, and full or sampling inspection before being sent.

Appearance Quality Inspection

First confirm whether the custom part meets your appearance requirements, such as the color, texture and other physical attributes of the product.

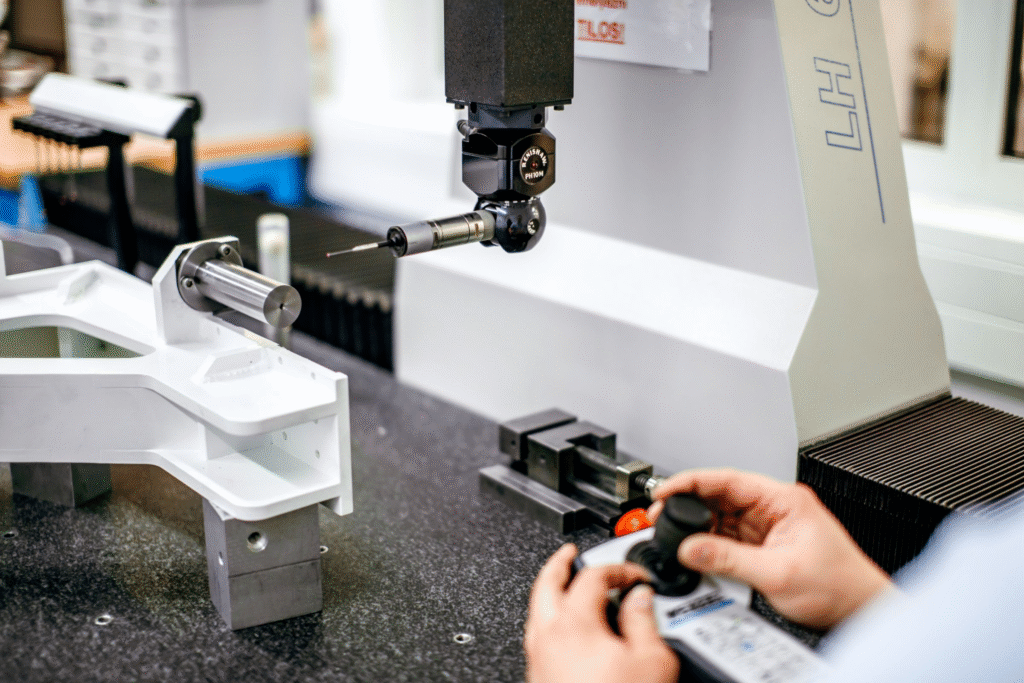

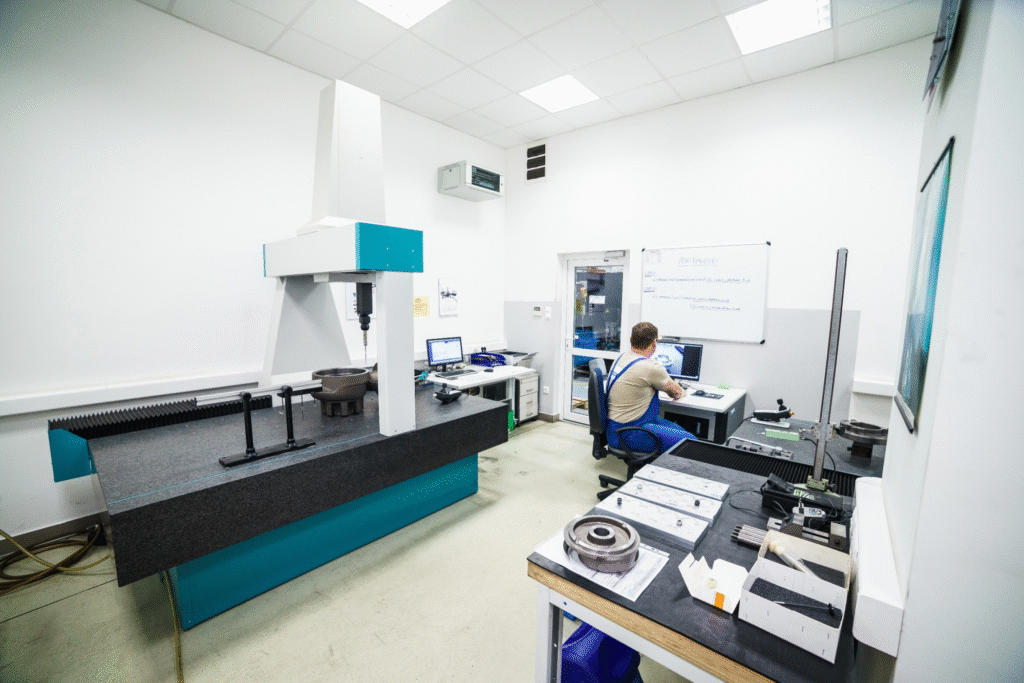

Dimensional

Inspection

For complex ones, a three-coordinate measuring machine is needed to accurately measure their dimensions.

Performance Inspection

Test the function and performance of parts and, in the case of parts with threads or tapped holes, check that the assembly meets requirements.

First Article

Report

At the final stage of the inspection process, we provide you with a final inspection report. The report outlines all inspection instruments and results.

What Our Clients Are Saying About VINLUK

Hear from our satisfied customers who have experienced the quality and value of our products and services.

Dan, thank you very much for your support.My project was a huge success, we may have exchanged hundreds of emails, thanks for your patience and high quality parts.

Jordan Smith

These samples look great and I think that we’ve played it perfectly safe on the knob dimensions. I’m ready to move forward with production.

Taylor Johnson

Nicole and the VINLUK team have become an invaluable supplier for our prototyping process, their response time is quick, their prices and lead times are great.

Casey Williams